Laser Cutting: The Ultimate Guide to How It Works, Benefits, Materials, and Applications in 2025

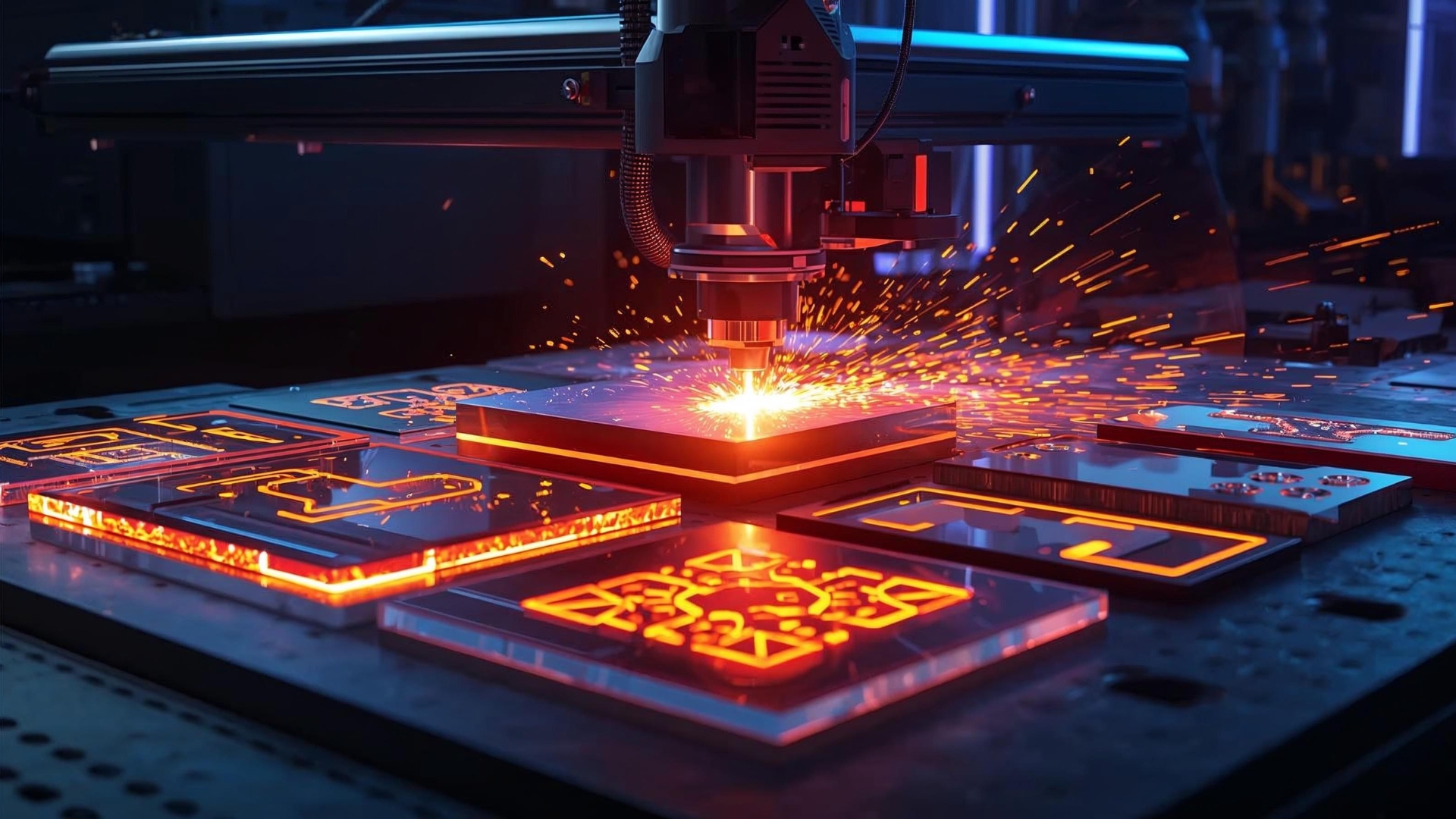

In 2025, laser cutting remains one of the most revolutionary technologies in manufacturing, prototyping, and creative industries. This precise, non-contact process uses a focused laser beam to melt, burn, or vaporize materials, delivering clean edges and intricate designs with unmatched accuracy. Whether you’re a hobbyist crafting custom signs or an industrial manufacturer producing aerospace components, laser cutting offers speed, versatility, and efficiency that traditional methods struggle to match.

This comprehensive guide covers everything you need to know about laser cutting in 2025, including how it works, types of lasers, best materials, advantages and disadvantages, applications, and the latest trends shaping the industry.

What Is Laser Cutting and How Does It Work?

Laser cutting is a thermal subtractive manufacturing process that directs a high-powered laser beam through optics to cut or engrave materials. The laser (Light Amplification by Stimulated Emission of Radiation) generates an intense beam focused to a tiny spot—often as small as 0.001 inches—creating extreme heat (up to 20,000°C) that melts or vaporizes the material.

The basic steps:

- A CAD file guides the CNC-controlled laser head.

- The beam hits the material, assisted by a gas jet (oxygen, nitrogen, or air) to blow away molten debris.

- The result: a precise kerf (cut width) with minimal heat-affected zone (HAZ).

In 2025, AI integration and real-time monitoring make the process even smarter, automatically adjusting parameters for optimal results.

Types of Laser Cutting Machines in 2025

Three main laser sources dominate the market:

| Type | Best For | Wavelength | Pros | Cons |

|---|---|---|---|---|

| CO2 Laser | Non-metals (wood, acrylic, fabric) | 10.6 μm | Excellent for organics, affordable | Higher maintenance, less efficient on metals |

| Fiber Laser | Metals (steel, aluminum, brass) | 1.06 μm | 3–10x faster on metals, low operating costs, cuts reflectives | Higher upfront cost |

| Diode Laser | Hobby/small-scale engraving & cutting | Visible/IR | Compact, cheap, easy to use | Lower power, limited thickness |

Fiber lasers now lead industrial applications in 2025, with powers exceeding 40 kW enabling thick-plate cutting that once required plasma or oxy-fuel.

Best Materials for Laser Cutting

Laser cutting works with an enormous range of materials. Here are the most popular in 2025:

| Material Category | Examples | Max Thickness (Typical 10–20 kW Fiber) | Notes / Best Laser Type |

|---|---|---|---|

| Metals | Mild steel, stainless, aluminum, brass, copper | Up to 50 mm steel | Fiber preferred |

| Woods | Plywood (birch/poplar), MDF, balsa | 20–30 mm | CO2 |

| Plastics | Acrylic (cast best), POM/Delrin, ABS | 20–30 mm acrylic | CO2 or fiber (marking) |

| Paper/Cardboard | Cardstock, corrugated | Unlimited (thin) | Any |

| Fabrics/Textiles | Leather, denim, felt | Multiple layers | CO2 |

| Foam & Rubber | EVA foam, neoprene | 30–50 mm | CO2 |

Materials to avoid: PVC (releases chlorine gas), fiberglass, polycarbonate (poor edge quality), and anything with chlorine or fluorine.

Advantages of Laser Cutting

- Unmatched precision — Tolerances as tight as ±0.005 mm.

- High speed — Fiber lasers cut thin metals 5–10× faster than traditional methods.

- Minimal waste — Narrow kerf (0.1–0.5 mm) and excellent nesting software.

- No tool wear — Non-contact process = no physical blades to replace.

- Complex geometries — Easily cuts intricate patterns impossible with mechanical tools.

- Automation-ready — Integrates with Industry 4.0, lights-out operation possible.

- Clean edges — Often requires no secondary finishing.

Disadvantages of Laser Cutting

- High initial investment for industrial machines.

- Limited thickness on very thick plates (>50 mm usually requires plasma/oxy-fuel).

- Heat-affected zone can cause hardening or warping in sensitive metals.

- Reflective materials (copper, brass) historically problematic (largely solved by modern fiber lasers).

- Fumes require strong ventilation/extraction systems.

Laser Cutting vs. Other Cutting Methods (2025 Comparison)

| Method | Precision | Speed (thin metal) | Thick Material | Cost per Part | Best Use Case |

|---|---|---|---|---|---|

| Laser (Fiber) | Highest | Fastest | Good (up to 50 mm) | Low–Medium | Precision parts, prototyping |

| Plasma | Medium | Fast | Excellent (>50 mm) | Low | Thick steel, shipbuilding |

| Waterjet | High | Slow | Excellent | High | Heat-sensitive materials |

| CNC Milling/Saw | Medium | Slow | Good | Medium–High | 3D features, very hard metals |

| Oxy-Fuel | Low | Medium | Excellent | Very Low | Very thick carbon steel |

In 2025, fiber laser has closed most gaps—it’s now the default choice for 90% of sheet-metal work.

Applications of Laser Cutting in 2025

- Automotive & EV battery tabs, chassis components

- Aerospace precision brackets, turbine blades

- Electronics enclosures, heat sinks

- Architecture & signage acrylic letters, decorative panels

- Medical devices surgical tools, implants

- Fashion & jewelry intricate leather/felt patterns

- Hobby & prototyping custom enclosures, models

Latest Trends in Laser Cutting (2025)

- Ultra-high-power fiber lasers (30–50 kW) for thick plates at record speeds.

- AI & automation — Self-optimizing parameters, predictive maintenance.

- Green/sustainable lasers — Lower energy use, air-assist cutting to reduce nitrogen.

- Hybrid machines — Combine laser with bending or welding in one setup.

- Blue & green lasers — Better absorption for copper/gold in EV and electronics.

Conclusion: Why Choose Laser Cutting in 2025?

Laser cutting delivers the perfect balance of precision, speed, and versatility for modern manufacturing. Whether you’re cutting thin acrylic for signage or thick stainless steel for industrial parts, today’s machines are faster, smarter, and more cost-effective than ever.

Ready to start your next project? Many service providers offer instant online quoting—upload your design and get parts in days.

Have questions about materials, design tips, or finding a laser cutting service near you? Drop a comment below!